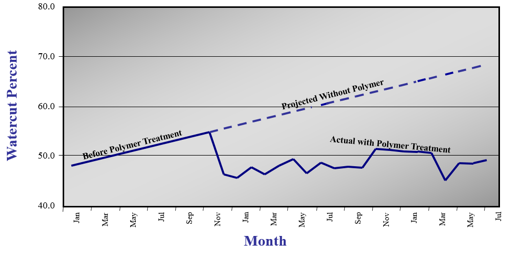

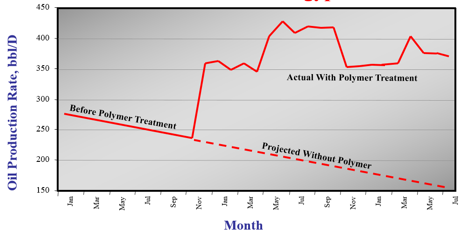

An industry leader and pioneer in evaluation, design, and field application of crosslinked polymer technology systems to combat excess water production from production wells, and redirect the injected fluids to the unswept, underswept zones in injection wells.

IPR is a pioneer in the analysis, design, and field application of crosslinked polymer technology for profile modification and conformance enhancement of production and waterflood injection wells. Cutting-edge conventional and harsh environment polymer gel systems are developed in our local and international laboratories and are field implemented by company designed high-tech mobile polymer plants, accompanied by mobile laboratories, stationed in the USA and abroad.

- Crosslinked Polymer Technology for Water Shutoff & Water Diversion

- Custom Built High-Tech Mobile Pumping Plants

- High or Low Shear Mixing

- Batch Mixing for Consistency and Quality Control

- Domestic & International Laboratory Facilities for Gel System Development & Testing

- Mobile Field Laboratories for Onsite Real-time Monitoring & Evaluation

IPR Oilfield Services has a comprehensive HSE program first compiled by professional third party specialists.

Process:

New employee orientation at the office level reviewing HSE policy, documentation, pre-screening and training.

Prior to field operations, IPR on-site HSE supervisors continue new employee training and orientation prior to engaging in actual work processes. The orientation involves hazard identification, site inspection, documentation training, and discussions of expectations with on site staff.

HSE for the seasoned team involves daily toolbox meetings, monthly training on site and monthly training at the Cairo offices. IPR maintains a matrix to track all employees are receiving all training courses required through the course of the year.

STOP program is implemented and a safety culture is maintained from the top down.

A culture of safety is of paramount importance to our company and we firmly believe each and every member of our organization has the right to a productive and safe environment and returns home without injury to their family each night. Health and Safety is an integral part of our daily operational routine. Equipment IPR equipment is API certified and IPR employs routine and rigorous inspection procedures to maintain API compliance.

Environment. IPR crews are trained to maintain a clean, trash free location, report and mitigate any spills or leaks immediately and maintain efficient operations to contain drilling fluids and cuttings. IPR uses new, fuel efficient equipment with daily consumption levels 50% lower than larger sized equipment routinely employed to perform the same drilling or well maintenance tasks.

Service Offerings

HSE Responsibility Program

IPR Oilfield Services has a comprehensive HSE program first compiled by professional third party specialists.

Process:

New employee orientation at the office level reviewing HSE policy, documentation, pre-screening and training.

Prior to field operations, IPR on-site HSE supervisors continue new employee training and orientation prior to engaging in actual work processes. The orientation involves hazard identification, site inspection, documentation training, and discussions of expectations with on site staff.

HSE for the seasoned team involves daily toolbox meetings, monthly training on site and monthly training at the Cairo offices. IPR maintains a matrix to track all employees are receiving all training courses required through the course of the year.

STOP program is implemented and a safety culture is maintained from the top down.

A culture of safety is of paramount importance to our company and we firmly believe each and every member of our organization has the right to a productive and safe environment and returns home without injury to their family each night. Health and Safety is an integral part of our daily operational routine. Equipment IPR equipment is API certified and IPR employs routine and rigorous inspection procedures to maintain API compliance.

Environment. IPR crews are trained to maintain a clean, trash free location, report and mitigate any spills or leaks immediately and maintain efficient operations to contain drilling fluids and cuttings. IPR uses new, fuel efficient equipment with daily consumption levels 50% lower than larger sized equipment routinely employed to perform the same drilling or well maintenance tasks.